In recent times, PVD coating has been demonstrated to have more benefits on base metal jewelry metal. But how is it done you might ask? Several methods can be utilized, a few of which include Physical Vapor Deposition (PVD), electroplating, Chemical Vapor Deposition (CVD), etc.

The method that we will be discussing is the most popular today, PVD coating. In this article, we will cover questions such as: What is PVD coating? How is PVD applied? What colors can be applied? All these questions will be answered plus many more.

Let’s jump right into it!

What is PVD Coating?

PVD, physical vapor deposition, is used to describe several thin-film deposition techniques. It involves the vaporization of solid material in a vacuum environment which is then deposited onto a substrate as an alloy composition coating or pure material. So, it is simply transferring the coating material to the desired item.

The method offers pure and high-performance coating as it involves the transfer of the coating material on a molecular level or as a single atom. Hence, it is the preferred method when carrying out metal coating. PVD coating is an essential component for performance in products such as optical lenses, self-cleaning tinted windows, displays, computer microchips, semiconductor devices, photovoltaic applications for solar panels, medical devices, and products that require a durable protective film like jewelry. If you’re looking for a pure, thin, clean, or durable coating, then PVD is the solution.

The two main types of PVD coating include Thermal Evaporation and Sputtering. Sputtering is the bombardment of the target material with a high energy electrical charge which causes molecules or atoms to “sputter off”. They are then deposited on a substrate like a solar panel or silicon wafer. Stainless Steel and titanium jewelry coating select this way, as it is easy to handle and control.

On the other hand, Thermal Evaporation involves the intense boiling of the coating material in a vacuum environment. A vapor stream is produced which then condenses on the substrate.

Benefits of PVD technology

There are a lot of benefits involved with using Physical Vapor Deposition. A few of which include:

- Excellent Adhesion

- Low Maintenance

- Uniform Coating

- High Hardness (Second only to Diamond)

- Brilliant Decorative Finish

- Environmentally Friendly Process

- Low Coefficient of Friction

- Superior Wear Resistance

- High Chemical Resistance

- High Corrosion Resistance

PVD Coating Application

Whether it is Thermal Evaporation or Sputtering, both methods involve the use of high vacuum techniques to vaporize a target material into atoms or molecules which are then deposited on a substrate (eg- jewelry). It is carried out within a vacuum chamber with pressures at 10-2 to 10-6 Torr (102 – 104 millibar), approximately the pressure of outer space. Temperatures normally range between 50 and 500° C.

The application process involves:

1) The product that you want to be coated (jewelry, doorknobs, etc) is placed in a chamber on racks.

2) The oxygen in the chamber is removed until the optimal pressure is obtained depending on the substrate and the coating material.

3) The coating material is added and heated, or an electronic charge is used to vaporize.

4) The vapor molecularly bonds to the substrates on the racks. (Sometimes the substrate to be coated is preheated before the vaporization process)

What is the PVD coating Jewelry process?

The process of PVD jewelry coating simply involves spraying/transferring the PVD coating material directly onto the surface of the target jewelry layer by layer at a molecular level.

In any case, here’s a more detailed procedure:

1) The metal jewelry is cleaned and prepped.

2) It is then placed inside a PVD vacuum chamber on a rack.

3) The oxygen in the chamber is removed until the optimal pressure is obtained depending on the type of metal jewelry and the coating material.

4) The coating material is added and heated, or an electronic charge is used to vaporize.

5) The vapor molecularly bonds to the metal jewelry on the rack. (Sometimes the jewelry is preheated before the vaporization process)

For jewelry, the PVD layer is normally 0.25 microns ~ 5 microns thick. The characteristics, including the thickness, of the PVD jewelry layer are dependent on a few controlled factors. These include temperature, type of coating substance, vacuum chamber pressure, reagent gas used and volume, and the coating thickness desired.

What kind of jewelry can use PVD Coating?

Physical Vapor Deposition (PVD) is a process that involves the permeation and bonding of coating material onto a base metal. Depending on the desired product, substrate materials, to which the coating is applied, may vary from alloys, metals such as stainless steel and aluminum, ceramics, nylon, plastic, glass, and just about any element/metal from the periodic table.

Some common jewelry materials used for PVD coating include:

- Titanium and stainless steel jewelry can do coating, without base layer. Tungsten also works.

- Brass/Copper usually need a nickle/chromium electroplated before PVD coating. While nickle and chromium will cause allergic reaction, so our brass/copper jewelry will not do PVD coating. We choose electroplating for them.

PVD is not only environmentally friendly, but it also provides a variety of brilliant finishes because of the different coating materials that can be used. The finish is extremely strong, durable, hypoallergenic, and long-lasting.

The Thickness of PVD Coating

The PVD coating layer is normally 0.25 microns ~ 5 microns thick, which is small. A human hair is 70 microns in diameter, which is to show you how slim the PVD coating layer is.

To achieve a uniform coating thickness (normally a few molecules thick), the material to be coated is rotated regularly and travels at a uniform speed through the vacuum chamber. It is possible to do single and multi-layered coatings in the same cycle.

BMJ PDV coating is 0.5 microns, for gold color coating, we do is 0.5 microns TiN and 0.06 micron Au. Which promise 2 years will not discolor.

Common Colors of PVD coating jewelry and the coating material

When you go shopping for PVD-coated jewelry, you can normally get them in a way array of colors. Some common colors that you can choose from include:

- Gold (coated with titanium nitride or other metal)

- Rose Gold (coated with zirconium, titanium, or another substrate)

- Black (coated with titanium aluminum carbonitride or molybdenum disulfide)

- Blue (coated with Titanium aluminum nitride)

- Bronze (coated with Titanium aluminum nitride)

- Chrome (coated with Hexavalent chromium)

- Yellow gold (coated with titanium nitride)

- Silver (coated with aluminum, titanium, Chrome, or Nitride)

- Platinum (coated with platinum)

- Dark red (coated with zirconium nitride)

These coatings will give you a piece of elegant, vintage-looking jewelry that is long-lasting and affordable.

PVD coating on stainless steel jewelry

When you think about stainless steel jewelry, a common silver color comes to mind. But since Physical Vapour Deposition coating was introduced, you are no longer just limited to that one color. There exists now a rainbow of colors from which you can choose your stainless steel jewelry.

PVD is carried out in a low-pressure chamber, and by varying the gases used and the processing time involved, a myriad of colors can be applied to your stainless steel jewelry. The resulting jewelry now looks as if it is gold, bronze, brass, or some other metallic jewelry. The simplified method is as follows:

1) The step involves cleaning the stainless steel jewelry to create a smooth surface for bonding.

2) The jewelry is added to a rack and placed in a PVD vacuum chamber with a coating metal.

3) The pressure is adjusted to produce a high vacuum level. Afterward, argon gas is introduced in a small amount.

4) A high electrical charge is applied to allow the argon ions to gain energy and in turn bombard the coating material to release atoms.

5) The released atoms are deposited onto the stainless steel jewelry as the coating.

This is known as Sputtering, a type of Physical Vapor Deposition. The newly applied coating will give the accessory new strength and shine. Some of the colors that can be applied include gold (TiN), rose gold (ZrN), blue (TiAlN), bronze (TiAlN), and dark red (ZrN), as well as black (TiAlCN).

Some of the benefits of applying a PVD coating to your stainless steel jewelry include:

- Thin surface layer – the underlying texture is still visible.

- Non-tarnish – The PVD colors give it a uniform look and will not fade very easily.

- Abrasion-resistant from the electrochemical processes

- Wear and weather-resistant – PVD coating increases the jewelry’s lifespan and reduces its maintenance. PVD coating lasts longer than any other coating of the same thickness applicable to jewelry.

PVD coating on titanium jewelry

PVD coating is not only applied to stainless steel, but it can also be applied to titanium jewelry. The method produces an eye-catching titanium accessory that retains its durability and biocompatibility. Methods is same as stainless steel jewelry.

How long does PVD coating last?

PVD coating can produce a long-lasting coat that can last for generations. It is highly durable and gives protection against daily cleaning. Traditional coating methods, such as electroplating of gold, nickel, and brass, produce clear coats that will degrade and fade over time.

Usually coating more thick, it will last long time.

The thickness of PVD coating for Jewelry VS Electroplating

For jewelry, the ideal PVD layer is normally 0.25 microns to ~ 5 microns thick. On the other hand, the electroplating of jewelry produces a layer of thickness of about 0.5 microns to ~ 3 microns thick.

Is PVD the same as ion-plated?

Yes, you can use both terms interchangeably. Physical Vapor Deposition (PVD) is also known as Ion plating. Ion plating, a PVD technique, is the concurrent bombardment of the substrate (material to be coated) with atomic-sized energetic particles from the coating material. Before deposition occurs, the prior bombardment is used clean the surface.

Testing Method of PVD coating

| Testing Description | Testing Method |

| PVD thickness | Calibration |

| the adhesion of the PVD Coating | Bending test |

| Impact test of the PVD coating | Hardness Vickers |

| Salt Spray Test | 48hrs ASTM B117 |

| Aging (Color fading) Test | Abrasion Resistance Test ASTM D 968 |

FAQs on Physical Vapor Deposition

Is Gold PVD Coating on Jewelry Real Gold?

Depending on the customer’s demand, gold PVD coating on a piece of jewelry may be real gold or it might not be. You can decide whether you want to use real gold to PVD coat your jewelry. The choice is left up to you.

Either way, gold or not, PVD coating will still enhance the look and properties of your jewelry. Additional coating materials able to give it a gold appearance include copper and brass. But if you want, you can use real gold.

Is PVD coating hypoallergenic?

Yes, PVD coatings are hypoallergenic and non-toxic, they will not cause any irritation to the skin.

Is PVD the same as ion-plated?

Yes, you can use both terms interchangeably. Physical Vapor Deposition (PVD) is also known as Ion plating. Ion plating, a PVD technique, is the concurrent bombardment of the substrate (material to be coated) with atomic-sized energetic particles from the coating material.

How to clean PVD coating?

To help you care for your PVD-coated accessories, here are a few guidelines:

- Use a soft, dry duster or cloth to clean regularly.

- Wash periodically with a soft cloth and a mild soap. Dry with a clean, soft cloth.

- PVD coatings can get fingerprints after a while. Fingerprints can be removed using mild soap and a soft cloth and then dried.

- When wiping or rubbing, try to do so in the direction of the polish lines. Avoid going across them or against them.

- DO NOT use oily or greasy rags to clean. DO not use bleach, acid-based, or caustic cleaning agents on your PVD-coated product.

- DO NOT use hard or abrasive materials against PVD-coated products.

Are PVD Coatings Safe?

Yes, you don’t have to worry. PVD-coated materials are relatively safe. Physical Vapor Deposition is an environmentally friendly method that produces little to no toxic by-products. To begin with, there are hardly any toxic materials used to create PVD coatings.

In addition, PVD coatings are used in the medical and surgical industry because they produce clean, pure, and durable coatings. So, if you can trust the doctor, you can trust PVD coatings.

Is PVD coating expensive?

No, PVD coating is not that expensive. This is a common misconception that many people have regarding PVD coating. The only significant cost is from sourcing the coating material. So, you can choose an expensive one or a cheap coating material.

Is PVD coating waterproof? Can you shower with your PVD-coated jewelry?

You don’t have to worry. PVD coating allows pieces of jewelry to be waterproof and resistant to wear, tarnish and sweat. So, you can enjoy your shower in your favorite PVD-coated jewelry.

What gas is used in PVD coating and why?

The gas that is normally used in PVD coating is argon gas. This is because it is a chemically inert gas and will not react with any other atoms or compounds during the coating process. This also means that the coating material in vapor form will remain pure before it is deposited on the substrate (material to be coated).

Reactive gases such as oxygen, nitrogen, and acetylene are occasionally used when a specific stronger coating is required. The gases will react with the coating and substrate to form stronger bonds. But argon gas is generally used.

What Makes PVD Coatings Highly Durable, Scratch, and Corrosion Resistant?

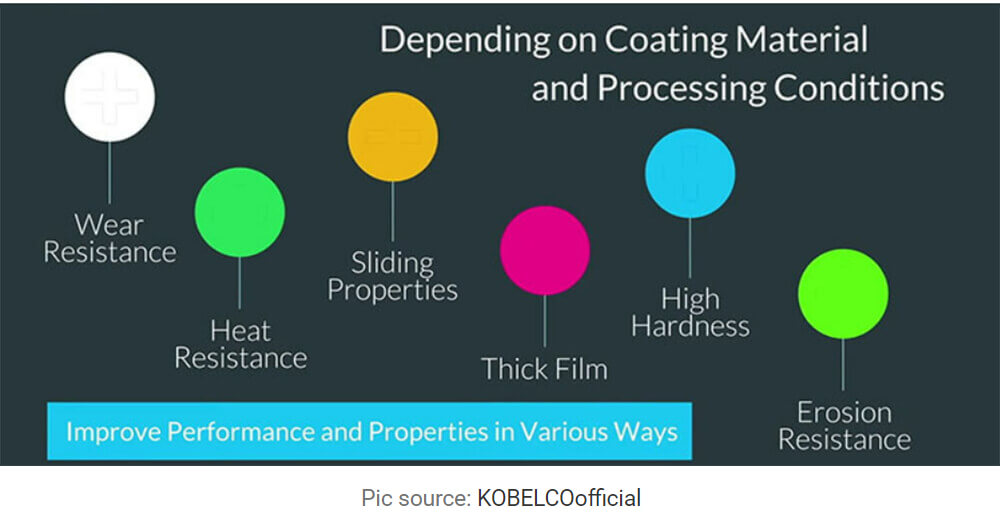

By utilizing certain coating materials, gases used and processes, it is possible to produce PVD-coated products with characteristics such as increased hardness, improved corrosion resistance, improved scratch resistance, increased lubricity, and more. So, the type of coating material and process involved are important in determining how durable and weather-resistant a PVD-coated material will be.

For example, by using titanium as the coating material, a strong and corrosion-resistant PVD coating can be applied. A PVD coating using platinum produces a brilliant finish that is scratch-resistant and long-lasting. Therefore, PVD is the preferred method of coating used in jewelry and decorative finishes.

Final Thoughts

There are two common methods of Physical Vapor Deposition: Thermal Evaporation and Sputtering. However, whether it is Thermal Evaporation or Sputtering, both methods involve the use of high vacuum techniques to vaporize a coating material (e.g- gold) into atoms or molecules which are then deposited on a substrate (eg- jewelry).

PVD is not only environmentally friendly, but it also provides a variety of brilliant finishes because of the different coating materials that can be used. The finish is extremely strong, durable, hypoallergenic, and long-lasting. So, if you’re looking for all these qualities in a piece of jewelry, then PVD-coating is the way to go.